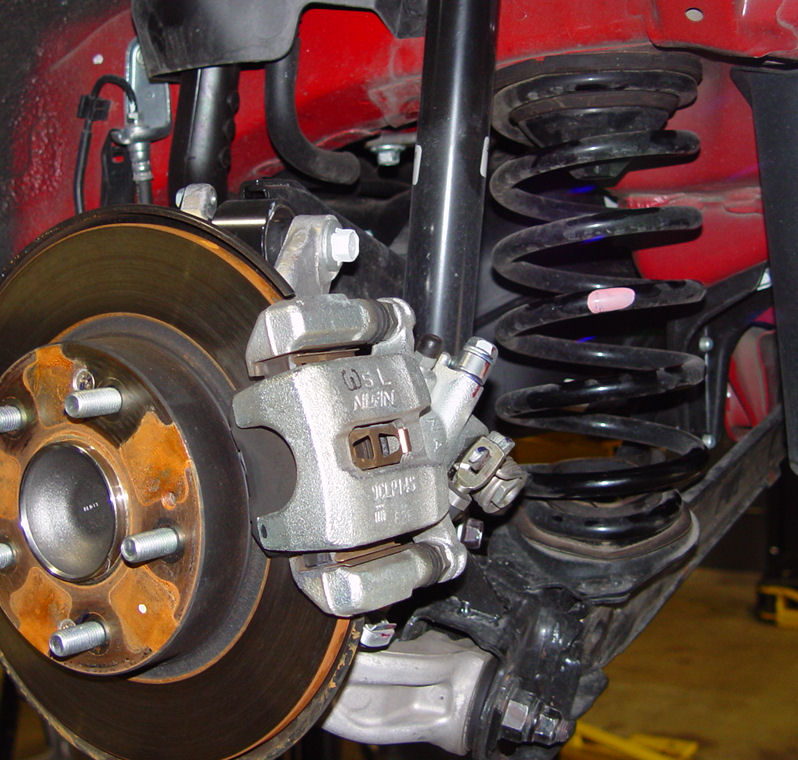

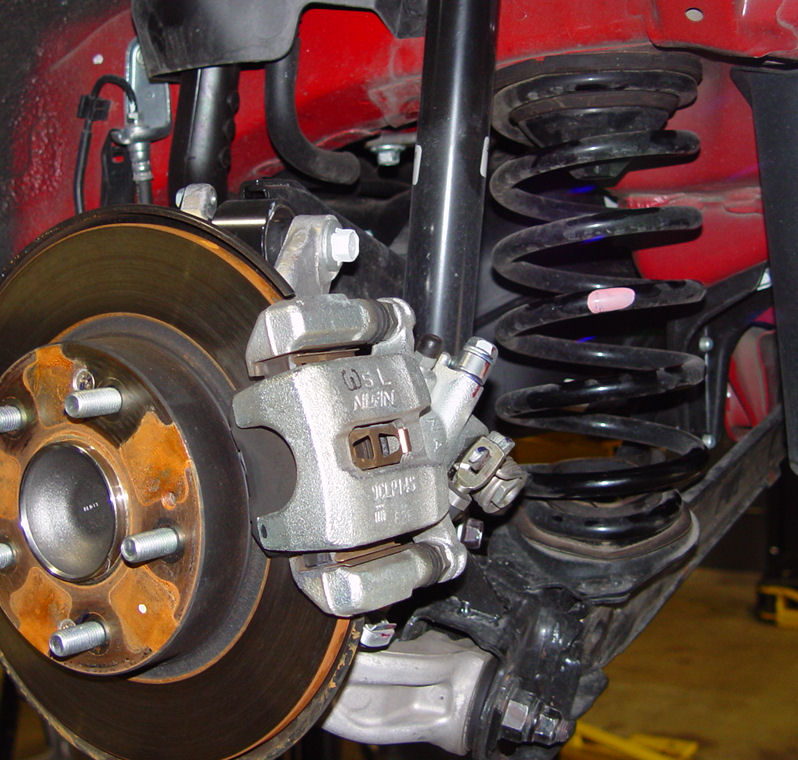

There are several types of springs that have been used in suspensions over the years. The three basic types most often used are leaf springs, torsion springs and coil springs. These different springs have been around for years and years. Leaf springs are still popular on trucks and vehicles that haul heavy loads because they are very stiff. The downside of leaf springs is that they are very heavy and take up a lot of space. Torsion springs are less common, but have been used in the rear suspensions of Porsches and are still used in the front of pick-up trucks. The way a torsion spring (which is usually steel) works is by resistance to a twisting motion. Torsion basically means to twist and a torsion spring is the twisting of a long bar. Coil springs are adaptations of a torsion spring differing by being wrapped around many times in a coil or helical shape. The principal of how it operates or resists rotation is the same. A coil spring, which can be seen in picture after the jump, illustrates how they look.

Coil springs work by resisting torsion that comes from being loaded or pushed together - often called compression springs. This resistance is what holds up the weight of your car. If there was no resistance or not enough your car would bottom out and bottoming out is not good. There are four variables that make up a coil spring and they are the length of the spring (L), diameter of the spring (D), diameter of the wire (d) and the numbers of coils (N). These variables all effect how resistant a coil spring is to compression. Coil springs have either closed ends or a plain ends and these ends can also be ground which gives the spring a flat appearance when looked at from the side. You can see this in diagram A. It’s important to consider the type of end because closed ends are considered to have one inactive coil at each end of the spring. An inactive coil is simply a coil that is not providing any resistance. Plain ends that are ground have a half an inactive coil at each end while plain ends have no inactive coils.

Since the number of coils is so important when calculating a spring rate it is vital to use the correct number of active coils. This leads us to spring rates and defining what that means. In general a spring rate (S) is pretty basic - units of load (force) per unit of deflection (compression). Typically spring rates are given in pounds per inch. S = Gd4/8D3N where G is the shear modulus of the spring material. Rule of thumb - when d increases, so does the spring rate and when D or N increase the spring rate decreases.

Next time someone’s talking about their 500 pound springs they mean their springs are rated at 500 lbs/in. Simply put, if you set 500 lbs on top of the spring it “should” compress by 1 inch. This would be a linear spring. It is safe to say that “linear” springs typically behave this way only over a given deflection range. This range is where suspension engineers try to keep the suspension travel operating within. Coil springs do a great job of supporting the weight of your car and resisting the huge loads it’s subjected to when cornering and braking. It’s also a very compact way of incorporating spring technology into the suspension of a car. We all know there is not a lot of space available in the wheel well and coil springs will be hard to improve upon when considering efficiency and cost.

Hopefully springs make a little more sense than they did before and you can better understand the subject should you choose to change springs on your car.