Vive La Differential!

One of the most complex systems to visualize in a car is the drivetrain—specifically how the power from the engine provides forward motion to the car. A train of gears and shafts somehow converts the linear motion of pistons going up and down to rotational motion (torque) that turns the wheels to move the car. And in sporting cars a differential proportions the aforementioned torque between the two drive wheels.

Quick Primer

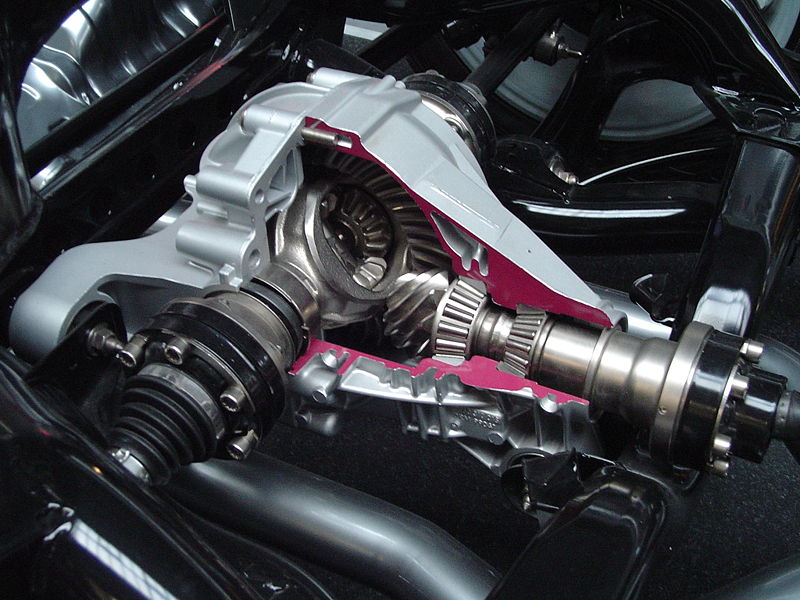

Power is supplied by the engine through the gearbox to the driveshaft which turns the drive axle. A pinion gear connected to the end of the driveshaft resides within the differential, which meshes with a large ring gear. This ring gear is attached to a carrier, which holds a set of three small planetary gears. The outer planetary gears can rotate in opposite directions relative to each other—which is important. The side gears drive the axle shafts which are attached to the wheels. Thanks to the fact that the planetary gears can rotate in opposite directions, the wheels can move in the same direction.

Basic Differential

Forget about the ring and pinion gear for a moment, since all they do is change the direction of rotation 90 degrees (from the driveshaft to the axle). What is important is the fact that a carrier is attached to the ring gear, and inside the carrier are three small planetary gears. The two outer planetary gears drive the axle shafts (sometimes called half shafts) which in turn drive the wheels. The entire carrier rotates with the ring gear, but inside the carrier, the side gears can counter-rotate relative to each other. This characteristic allows the wheels to move at different speeds, such as when the car is turning. The outside wheel travels a bigger arc and thus rotates faster than the inside wheel. If the wheels were directly linked, the axle would bind or one of the wheels would slip or hop.

Differentials allow the flexible distribution of drive torque between the wheels and the axle, which allows different rates of rotation from side to side. Unfortunately the mechanics being what they are, the power escapes to the side with the least torque requirement—it takes the easy way out in other words. For example, when you power out of a corner, the car’s weight (and consequent traction) shifts to the outside wheel. A standard open differential will send most of the torque to the inside (lower traction) wheel creating a bunch of unholy smoke and very little forward motion. Enter the limited slip differential.

Limited Slip Differential

A limited slip differential (LSD) does not allow the difference in speed of the axle shafts to increase beyond a predetermined amount, in other words it limits the speed difference between the two wheels. Instead of all the power escaping through the inside wheel as in the above example, the limited slip differential will “lock” the two wheels together somewhat, and more of the available power will be transferred to the outside wheel with more traction.

There are two main types of LSDs used on modern cars, the torque sensitive type that employs a single clutch or gears and the speed sensitive type which uses a clutch pack or a viscous fluid.

Gear Ratios

A gear ratio in the mechanical world is simply the difference in the number of teeth on the input gear versus the output gear. Let’s say the pinion gear on the end of the drive shaft has 15 teeth. It meshes with a ring gear in the differential that has 48 teeth. The resulting ratio is 48/15th or 3.20. This means the driveshaft will turn 3.2 times for each revolution of the ring gear. The higher the number the faster the driveshaft (and consequently the engine) needs to turn for each revolution of the wheel.

The driveshaft is connected to the transmission-- which has its own set of gears-- and the ring gear is attached to the wheels via the half shafts. If you add up all the gears (and wheel diameters) between the engine and the road, you can calculate the speed the car will travel at any given RPM in any given transmission gear. The formula to figure out the speed of a car at a given engine RPM is as follows: multiply the circumference of the tire by the engine speed and divide it by product of the gear ratio of the transmission times the gear ratio of the differential.