Cracking up: E46 Sub-frame issues Part 1

There is no doubt that the BMW E46 3 Series line up of cars is great. They are right sized, relatively efficient to operate and have superb all around performance. But there are critical weaknesses in the chassis-- especially in the M3 version-- that need to be addressed. We already reported on the fatigue issues with the front strut tower in an earlier blog entry. This time we will focus on the rear subframe.

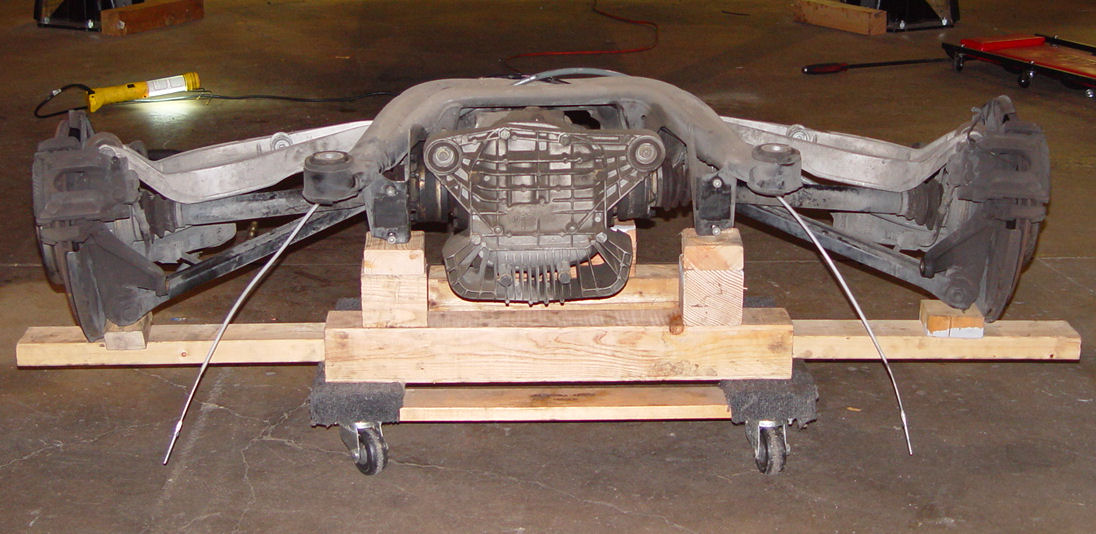

First a little background. The above drawing shows the rear sub frame assembly (sometimes referred to as an axle carrier) for an E46 M3. The differential nests within the box like frame and the suspension attaches to it. Below you see the sub-frame assembly on the car:

The complete sub-frame with attachments removed from the car:

Talking about sub-frame failures is a bit of a misnomer since it is the mounting points on the body that fail, not the sub-frame itself. The sub-frame is bolted to the body at four locations, and isolated by rubber bushings. When torque is sent through the axle and to the wheels, a moment is applied to the sub-frame. The sub-frame is also subjected to impact forces from the road surface (though much of the impact force is directed towards the shock and spring mounts, not the sub-frame). Over time, the forces begin to fatigue the sheet metal of the body.

Below is a photo of the right side front sub-frame mounting point. You can see the outside sheet metal has not only cracked, but chunks have broken off:

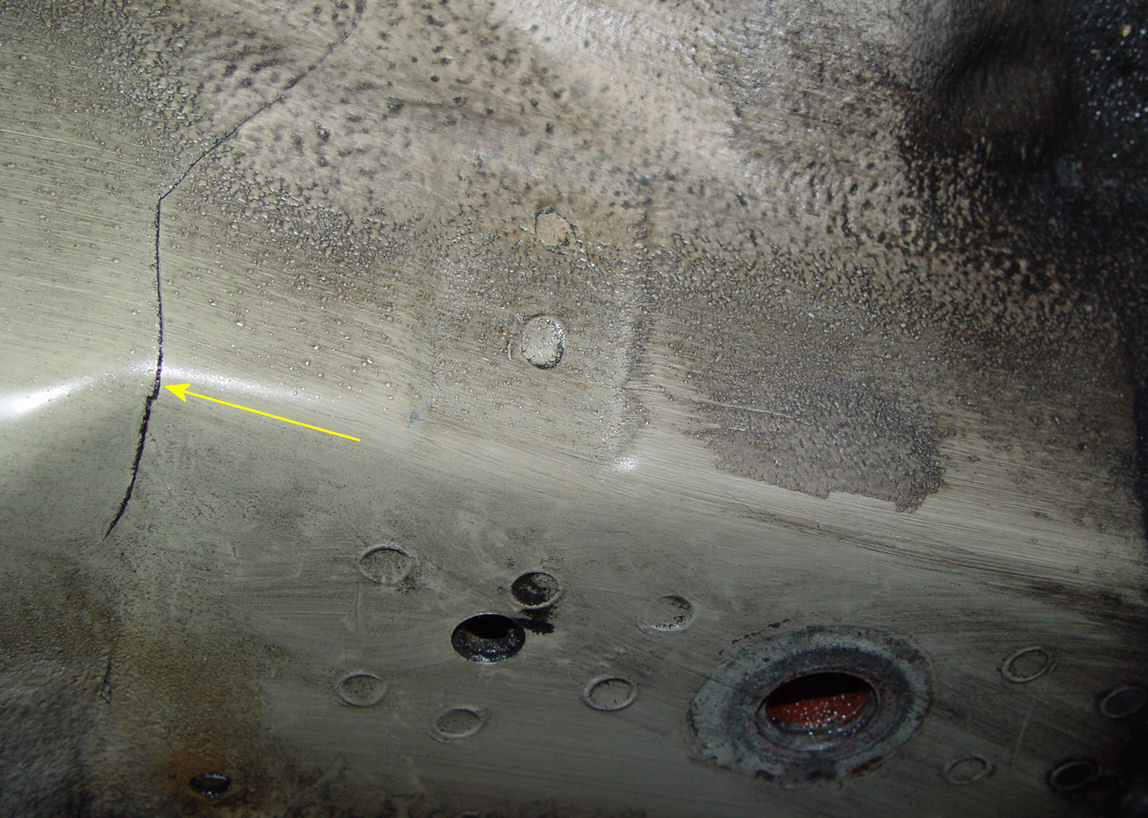

Here is a photo of the left rear mounting point failure:

Thanks to road grim that builds up on the chassis and the limited access to the mounting points, it is extremely difficult to spot these types of failures without removing much of the rear suspension or taking out the sub-frame all together. The car from which these photos were taken showed a slight compression on the right side rear which indicated something was wrong-- but it could have just as easily been a bad spring as a sub-frame mounting failure.

The fix is relatively simple, though it is quite involved. After the sub-frame is removed (along with all the suspension, driveline, brakes and gas tank) the mounting areas are inspected. We next grind away the paint and body filler. Simple cracks are first prepped and then welded. We custom cut, form and weld new sheet metal for the areas where metal is missing (as in the above example). As a precaution, we reinforce the mounting areas with extra steel plate and weld. The bare metal is then cleaned, primed and repainted before the sub-frame is re-attached. (A future entry will detail these final steps)

Some of the risk factors are:

Carrying heavy electronic equipment such as aftermarket sub-woofers and amps in the trunk

Installing heavy duty aftermarket sub-frame bushings that do not isolate shocks as well as the softer OEM bushings

Driving regularly on bad roads, particularly washboard dirt roads

Driving the car at track events

Repeated hard launches (launch control on SMG equipped cars)

Comments

Would you worry about this issue when contemplating the purchase of low miles 323 or 325 e46 that has apparently been well maintained and sensibly driven?

"No, we would not be too concerned about this on regular, well taken care of E46s. But it is something to check out if you have the chance."

-VRP

Posted by: John Prizer | July 4, 2009 06:25 PM

Just bought an '05 M3 ZCP with 15k miles. All stock. I plan to get BMW to do an inspection but even if no issue, do you recommend taking preventive reinforcing steps?

Reply

Depends on what your driving style will be. For normal use I would say no. But if you plan on going to the track often, or you drive on terrible roads frequently I would say reinforcing the rear pick up points would be a good long term investment. Turner Motorsports sells kits with ready made pieces for welding.

Posted by: Bryan | October 8, 2009 10:20 AM